| 4. Plastic recycling projects. |

| Recycling refers to the process of collecting used materials which is usually considered as ‘waste’ and reprocessing them. In this process these used materials are sorted and processed to be used as ‘raw materials’ for the production of new products. Recycling varies from ‘re-use’ in the sense that while re-use just means using old products repeatedly, recycling means using the core elements of an old product as raw material to manufacture new goods. Some of the most common items that are recycled are plastic, glass, paper, batteries, Aluminium etc. |

| Why is Recycling Important – |

| Recycling is need of the day and very important as - |

|

Recycling Saves Energy |

|

Recycling Saves Environmental Conditions and Reduces Pollution |

|

Recycling Saves Natural Resources |

|

Recycling gives Economic Benefits |

|

Recycling process creates employment opportunities |

|

Recycling Saves Space for Waste Disposal |

|

Recycling is necessity of the time. |

WHAT IS RECYCLING?

Recycling refers to the process of collecting used materials which are usually considered as ‘waste’ and reprocessing them. In this process these used materials are sorted and processed to be used as ‘raw materials’ for the production of new products. Recycling varies from ‘re-use’ in the sense that re-use just means using old products repeatedly, where as recycling means using the core elements of an old product as raw material to manufacture new goods.

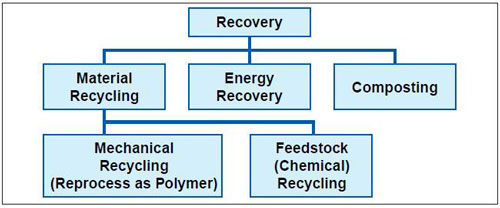

A typical recycle matrix

PE/PP recycling technology is the most mature and common case among all polymers. PE/PP recycling technology is the most mature and common case among all polymers.

Recycled PE/PP can be used again to produce plastic products, e.g. Bottles, containers, bags, sheets, films etc. For various packaging applications. Recycled PE/PP can be used again to produce plastic products, e.g. Bottles, containers, bags, sheets, films etc. For various packaging applications.

This recycling chain not only reduces the pollution to environment but also reduces production cost. This recycling chain not only reduces the pollution to environment but also reduces production cost.

The recycled materials can be used solely or blended with the virgin materials as per choice and end use. The recycled materials can be used solely or blended with the virgin materials as per choice and end use.

Recycled materials granulated on the underwater granulator with die face cutter, having uniform bulk density like virgin materials, can be used with automated loading systems. Recycled materials granulated on the underwater granulator with die face cutter, having uniform bulk density like virgin materials, can be used with automated loading systems.

|

| We supply world class recycling projects for- |

|

Postconsumer PP/PE materials, Nylon, ABS, and other engineering plastics. |

|

Post consumer PET bottles recycling, R-PET, Bottle to Bottle grade, suitable for food grade application. |

|

Project is originated from European manufacturer “SIKOPLAST” a leading name in recycling technology. |

| |

|

| |

Top |